First-mile cold storage is the practice of positioning precooling and refrigeration assets as close to the point of harvest as possible. In Madera, this strategy is not merely a logistical convenience; it is an essential component of maximizing Return on Investment (ROI). By eliminating the “thermal debt” that crops accrue during long-distance hauling to distant hubs, growers can preserve the cellular integrity of their products, ensuring they command the highest possible market premiums.

The Science of Field Heat

To understand the economics of first-mile cooling, one must first understand the physiological combat occurring within the crop immediately following harvest. When a grape, almond, or citrus fruit is picked, it does not immediately “die.” Instead, it enters a state of rapid respiration. It is still consuming its own sugars and moisture to maintain cellular function, but without the life-support system of the parent plant, this process leads to rapid degradation.

Thermal Inertia and Respiration Rates

Field heat is the enemy of shelf life. The temperature of a crop at the moment of harvest—often exceeding 90°F in the Madera summer—acts as a catalyst for enzymatic activity. This “thermal inertia” means that once a bin of produce is heated, it stays heated unless an external force aggressively removes that energy. For every 10°C (18°F) increase above the optimal storage temperature, the rate of respiration—and thus the rate of decay—doubles or even triples.

In an operationally transparent model, we look at “time-to-temp” as our primary KPI. If a commodity stays at field temperature for six hours versus two hours, the cumulative loss of turgidity (the internal water pressure that keeps fruit crisp) is non-linear. By the time that product reaches a port-adjacent cooler 100 miles away, it has already surrendered a significant portion of its sellable weight and nutritional profile. This is what we call “cellular exhaustion.”

Preserving Turgidity for Market Premiums

Turgidity is the difference between a “Premium” grade and a “Standard” grade. In the export market, where Madera’s almonds and table grapes often head, buyers pay for weight and texture. If a shipment loses 2% of its mass to evaporation during a long drayage haul to a Fresno or Bay Area facility, the grower is essentially leaving money on the tarmac. First-mile cooling in Madera halts this evaporation almost instantly, locking in the water weight and ensuring the product arrives at the end-user with the “snap” and juice content that domestic and international retailers demand.

Drayage vs. Quality

Logistics and biology are often at odds in the Central Valley. Traditionally, many growers have utilized large, centralized cooling hubs in Fresno or near major ports. However, the hidden costs of this “long-haul” cooling model are becoming unsustainable. When we analyze the economics of drayage (the transport of goods over a short distance), we must factor in more than just diesel surcharges and driver hours; we must factor in the “Quality Tax.”

The Hidden Cost of Transit-Time Respiration

When a trailer loaded with field-warm product sits in traffic on Highway 99, it is not just burning fuel; it is burning equity. The interior of a non-refrigerated or poorly precooled trailer can act like an oven. Even with “reefer” units running, if the field heat wasn’t removed at the source via forced-air or hydro-cooling, the unit is merely fighting a losing battle against the core temperature of the pallets.

Furthermore, diesel surcharges and the rising cost of Specialized Transport (reefer units) make long-distance drayage a significant line-item expense. By utilizing first-mile cold storage in Madera, growers can transition their product from “hot” to “stasis” within a 15-mile radius of the orchard. Once the product is stabilized at 34°F, the logistical pressure eases. A stabilized product is far more resilient to transit delays than a “breathing” product.

Data-Driven Comparison

To illustrate the operational impact, consider the following metrics comparing source-adjacent cooling in Madera to the traditional model of hauling to port-adjacent facilities.

| Metric | Madera Source Cooling | Port-Adjacent Cooling |

|---|---|---|

| Time to Stasis | 2-4 Hours | 8-12 Hours |

| Water Weight Loss | <0.5% | 1.5% – 3% |

| Transport Cost | Low | High (Drayage) |

As the table demonstrates, the “Time to Stasis” is halved or even quartered when cooling occurs at the source. This reduction in time directly correlates with the “Water Weight Loss” metric. For a grower moving 1,000 tons of produce, a 2% difference in weight loss represents 20 tons of product that literally vanished into thin air. At market rates, that is a six-figure loss attributed solely to the location of the cooling facility.

The Madera Advantage

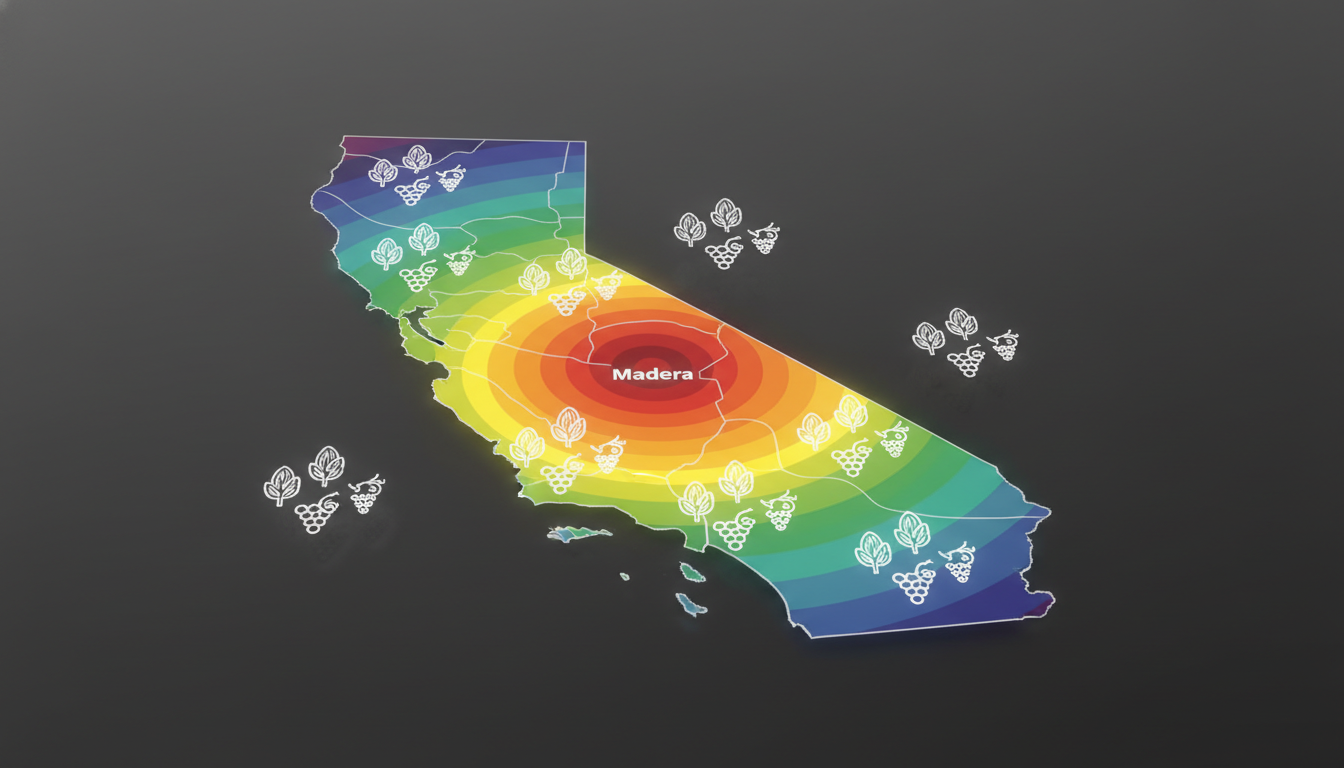

Why Madera? The geography of the San Joaquin Valley dictates that proximity to the “Golden State” logistics corridor is essential. Madera sits at the heart of the northern valley’s production zone, offering a strategic pivot point between the harvest fields and the outbound ports of Oakland or the distribution hubs of the Pacific Northwest.

Strategic Proximity to Production

By positioning cold storage assets in Madera, we are effectively shortening the “hot chain.” Madera’s infrastructure allows for immediate intake of diverse commodities, from pistachios and almonds to fresh stone fruit. This proximity reduces the vibration and mechanical damage that often occurs during long hauls on uneven field roads. A shorter trip to the cooler means fewer bruised berries and fewer cracked shells.

For a detailed breakdown of how this compares to neighboring hubs, see our analysis on Fresno vs. Madera Cold Storage: Why First-Mile Location Matters. The primary takeaway is that while Fresno offers scale, Madera offers immediacy. For high-value, high-respiration crops, immediacy is the only metric that matters for ROI.

Operational Transparency in Storage

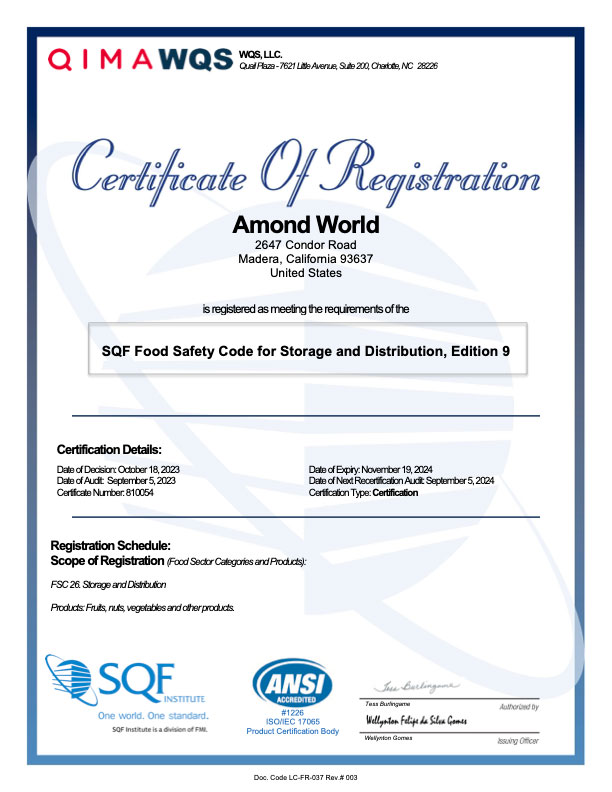

Modern first-mile facilities in Madera are not just warehouses; they are precision instruments. Using IoT-enabled sensors, we can track the core temperature of a pallet in real-time. This level of operational transparency allows growers to see exactly how quickly their “thermal debt” is being paid off. We can provide data that proves the product was brought to stasis within the critical four-hour window, providing a “Certificate of Freshness” that can be used to negotiate higher prices with wholesalers.

Reducing the Carbon Footprint

Beyond the immediate financial ROI, there is the ESG (Environmental, Social, and Governance) component. Reduced drayage means reduced carbon emissions. By cooling locally and then consolidating loads for efficient long-distance transport, Madera growers are participating in a more sustainable supply chain. This is increasingly important as retailers like Walmart and Whole Foods demand “Scope 3” emission disclosures from their suppliers.

Conclusion: The Bottom Line on ROI

In the world of agricultural commodities, we often focus on yields—bushels per acre, tons per hectare. But true profitability is found in the percentage of that yield that actually reaches the consumer in peak condition. First-mile cold storage is the insurance policy that protects the labor and capital invested in the growing season.

The economics are clear: Madera-based cooling reduces shrink, preserves sellable weight, and slashes the logistical costs of long-distance drayage. In an industry where margins are often thin, the ability to eliminate a 2% moisture loss and reduce diesel expenses by 15% is the difference between surviving and thriving. Thermal inertia is the enemy, and proximity is the only solution.

Frequently Asked Questions

- Q: Why Madera over Fresno?

A: Madera offers closer proximity to the orchards of the northern San Joaquin Valley, significantly reducing transit-time respiration and getting product into stasis faster than hauling into the congested Fresno metro area. - Q: How does first-mile cooling affect shelf life?

A: By removing field heat within the first 2-4 hours, you effectively “pause” the aging process, often extending shelf life by 3-7 days depending on the commodity. - Q: Is the cost of local cooling offset by the savings?

A: Yes. The savings from reduced water weight loss (shrink) and lower drayage fees typically far outweigh the per-pallet cooling cost.

Ready to protect your margins and maximize your harvest’s potential?