In the high-stakes world of temperature-controlled logistics, the margin for error is non-existent. For decades, the relationship between a brand owner and their Third-Party Logistics (3PL) provider was built on “blind trust.” A product would enter a warehouse, the doors would close, and the brand owner would hope that the environmental conditions remained stable until the product was shipped. This “black box” approach to storage is no longer tenable. As high-value commodities like biologics, specialty pharmaceuticals, and premium perishables dominate the market, the industry is shifting toward a new paradigm: the Truth Source.

As a Logistics Technology Specialist, I have seen firsthand how the lack of data transparency can cripple a supply chain. When a shipment arrives compromised, the subsequent investigation often turns into a game of finger-pointing due to fragmented data. The ‘Truth Source’ philosophy, pioneered by CVCS through our proprietary Goose system, eliminates this ambiguity. It establishes an immutable, real-time digital record of a product’s journey, ensuring that data is just as valuable as the cooling itself. In this new era, operational transparency isn’t just a luxury—it is the gold standard of the cold chain.

Moving Beyond the Black Box

The traditional 3PL model has historically operated in a state of data latency. In this “black box” scenario, temperature logs are often collected manually or downloaded from local sensors only after a period of time has elapsed. If a cooling unit fails on a Tuesday, the warehouse manager might not catch the deviation until a manual check on Wednesday, and the enterprise partner might not find out until a week later when the monthly report is generated. By then, the integrity of the product is already in question, and the financial loss is solidified.

The ‘Truth Source’ concept represents a radical departure from this reactive stance. It is built on the foundation of continuous, real-time connectivity. By integrating advanced IoT (Internet of Things) sensors directly into the infrastructure and feeding that data into a centralized portal, we eliminate the “data gap” between the physical warehouse floor and the corporate boardroom. At CVCS, this is achieved through our Goose system, which acts as the heartbeat of our operations.

Why is this shift happening now? The regulatory landscape is a significant driver. Modern standards, such as the FDA’s Food Safety Modernization Act (FSMA) and various international pharmaceutical guidelines, demand more than just “good results”; they demand proof of process. A ‘Truth Source’ provides that proof. It offers a chronological, unalterable history of temperature, humidity, and movement. When an auditor asks for documentation, a ‘Truth Source’ provider doesn’t hand over a stack of handwritten logs; they provide a link to a secure, real-time data stream.

Furthermore, accountability is no longer a post-mortem exercise. With real-time sensors, the system becomes proactive. If a sensor detects a deviation outside of the pre-set parameters, alerts are triggered instantly. This transparency creates a level of accountability that was previously impossible. The warehouse staff, the logistics managers, and the end clients all see the same data at the same time. This shared reality is the essence of the ‘Truth Source’.

Digital Twins of the Cold Chain

To understand the ‘Truth Source’ at a technical level, we must look at the concept of the “Digital Twin.” In logistics, a Digital Twin is a virtual representation of a physical product or process. When a pallet of sensitive cargo enters our facility, it is assigned a digital identity within the Goose system. This identity is mapped to its physical location and its specific environmental requirements.

This Digital Twin is constantly updated with data points:

- Ambient Temperature: Precisely tracked to within fractions of a degree.

- Relative Humidity: Critical for prevents spoilage or degradation of packaging.

- Inventory Status: Real-time tracking of SKU-level movements.

- Gate Logs: Exact timing of when a product was moved from a refrigerated zone to a loading dock.

By creating a Digital Twin, we provide our partners with 100% visibility. You are no longer just storing “Product X” in “Room Y.” You are monitoring a dynamic digital asset that reflects the health of your physical inventory. This level of granularity is essential for high-value inventory management. It allows for advanced strategies like FEFO (First-Expired, First-Out) to be executed with surgical precision, reducing waste and optimizing shelf life.

The integration of the Goose System for Real-Time Inventory Visibility ensures that this ‘Truth Source’ is accessible from anywhere in the world. Whether you are a logistics coordinator in a different state or a CEO at a global headquarters, the data remains consistent. This “single version of the truth” prevents the discrepancies that often lead to shipping errors or inventory write-offs. When everyone looks at the same dashboard, decisions are made faster and with higher confidence.

| Feature | Traditional 3PL | CVCS ‘Truth Source’ |

|---|---|---|

| Temp Logs | Weekly/Manual | Continuous/Real-Time |

| Inventory | Delayed Sync | Instant Portal Access |

| Visibility | Limited | 100% Transparency |

Empowering Enterprise Decisions

The ultimate value of a ‘Truth Source’ is not just in the data collection itself, but in how that data empowers enterprise-level decision-making. Recent industry surveys indicate that 90% of supply chain leaders believe visibility is the most critical factor for success. In a volatile market, the ability to pivot based on accurate data is a competitive advantage.

Consider the impact on risk mitigation. In the traditional model, a product recall is a nightmare of tracing lot numbers through various disparate systems. With a ‘Truth Source’, the trace-back process is instantaneous. You can pinpoint exactly which pallets were in which zone at which time, and verify their environmental history. This precision can save a company millions of dollars by narrowing the scope of a recall from “everything produced this month” to “the specific three pallets affected by a localized event.”

Moreover, the ‘Truth Source’ concept facilitates better financial planning. Real-time inventory visibility allows for leaner supply chains. When you know exactly what you have and where it is, you can reduce safety stock levels and improve capital flow. The Goose system’s portal provides insights into velocity and dwell time, helping brands understand their burn rate and optimize their production schedules accordingly.

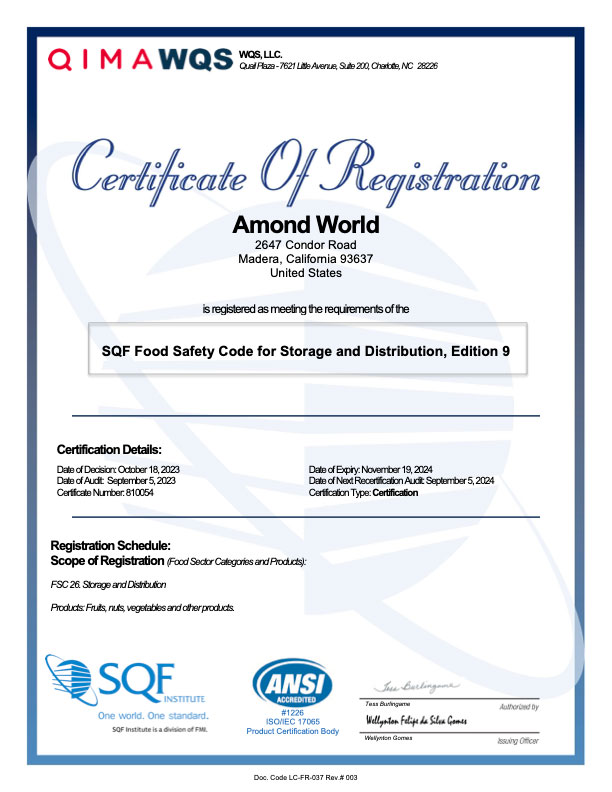

Operational transparency also builds brand equity. In today’s market, consumers and retailers are more discerning than ever. They want to know that the products they receive have been handled with care. By partnering with a 3PL that provides a ‘Truth Source’, brand owners can provide their own customers with certificates of integrity backed by hard data. It transforms the logistics provider from a cost center into a value-added partner that protects the brand’s reputation.

Finally, the ‘Truth Source’ prepares organizations for the future of automation and AI. Machine learning algorithms require clean, high-fidelity data to provide meaningful insights. By establishing a ‘Truth Source’ today, companies are building the data sets necessary to leverage the predictive analytics of tomorrow—forecasting demand spikes, predicting equipment maintenance needs, and further streamlining the global cold chain.

The Truth Source FAQ

Q: What is a Truth Source in logistics?

A: It is a single, verified point of data that all stakeholders can trust for compliance and operational decisions. It eliminates data silos and provides an immutable record of the physical state of goods.

Q: How does the Goose System maintain this ‘Truth Source’?

A: The Goose System integrates directly with warehouse sensors and inventory management protocols to provide a real-time, 24/7 stream of data to our clients via a secure web portal. This ensures that the data you see is the most current and accurate representation of your inventory.

Q: Does this level of transparency increase costs?

A: While the technology requires investment, the ‘Truth Source’ model actually reduces long-term costs by eliminating waste, reducing the risk of total-loss claims, and streamlining administrative tasks related to auditing and compliance.

Conclusion

The cold chain is no longer just about moving boxes from Point A to Point B at a certain temperature. It is about the data that travels with those boxes. The ‘Truth Source’ concept is the industry’s answer to the complexities of the modern global economy. By leveraging the Goose system, CVCS is leading the charge in providing the transparency, accountability, and reliability that enterprise partners demand.

In a world where 90% of leaders agree that visibility is the key to success, can you afford to keep your products in a black box? It is time to embrace a higher standard of logistics. It is time for the Truth Source.

Ready to see your supply chain in a new light?