At Central Valley Cold Storage, we are dedicated to providing state-of-the-art refrigerated cold storage solutions that increase grower and processor profitability and ensure the highest standards of food safety. We address a major challenge in the food supply chain, which is what happens to crops post-harvest before they reach food manufacturers and, ultimately, consumers. This is the least monitored part of the food supply chain, but one that is critical to supporting both food supply robustness as well as health and safety.

Central Valley Cold Storage’s integrated technology and sustainability approach enables us to be one of the most operationally efficient cold storage facilities in the country. Our CO2 refrigeration system uses 100% sustainable inputs, and our microgrid power production system makes us the largest cold storage facility in the U.S. to operate without any dependence on the electric grid. We believe that we are operating at 50% of the cost of comparable grid-connected buildings, and more importantly, our onsite power production enabled us to locate our facility in the heart of the Central Valley where we can truly be in the “first mile” of the food production industry.

Most agricultural crops are harvested seasonally. Farmers typically only harvest their crops in specific time windows to supply large markets around the world. However, the demand for fresh and organic produce products remains high year-round.

This combination of short harvest periods, high harvest volume, and constant high demand creates a bottleneck in the fresh and organic produce supply chain. Farmers face the pressure to sell their crops as quickly as possible, yet they don’t receive payment until their shipment is delivered to markets. This forces farmers to settle for a lower price post-harvest and creates severe time constraints throughout the supply chain. It also leads to price fluctuations throughout the year – crop prices are lowest at harvest and rise throughout the year until the next harvest season. Without adequate storage options, farmers lose out on annual crop revenue.

Farmers often store their crop on-site in bins covered with tarps before the crops are shipped. This outdated practice invites needless crop loss or degradation from insects, fungus, and mold, as well as general loss of freshness. Our state-of-the-art refrigerated cold storage is a revolutionary solution that bridges the gap between seasonal supply and constant high demand, increasing grower profitability.

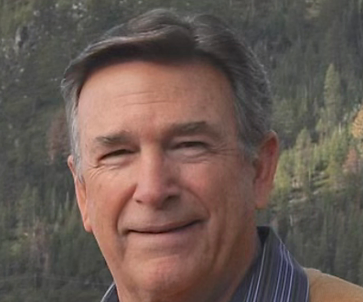

Plant Manager

With over 20 years in cold storage and processing, Alex A’Costa specializes in ag commodities. He has managed transportation, shipping/receiving, inventory, and quality control. Certified in Food Safety, HACCP, PDCA, CPR/First Aid/AED, EMR, and as a forklift and heavy equipment trainer, Alex is skilled in plant facilities and safety practices. Raised in the Central Valley, he is dedicated to his community. Alex ensures careful handling and timely delivery of all products.

Contact:

Alex.Acosta@centralvalleycoldstorage.com

Office: (559) 481-8559

Office: (559) 774-4352

Shipping & Receiving

Contact:

Iris.Velasquez@centralvalleycoldstorage.com

Office: (559) 481-8559

(August 29, 1945 – January 6, 2024)