FSMA 204, officially known as the “Requirements for Additional Traceability Records for Certain Foods,” is designed to facilitate faster identification and rapid removal of potentially contaminated food from the market. For processors handling items on the Food Traceability List (FTL)—which includes everything from nut butters and fresh-cut produce to leafy greens and melons—the days of manual spreadsheets and paper logs are numbered. This guide provides an authoritative roadmap to ensure your facility is not just compliant, but optimized for the digital future of food safety.

What is FSMA 204?

At its core, FSMA 204 is a traceability rule that mandates a standardized approach to recordkeeping across the entire supply chain. While previous regulations required “one step forward, one step back” traceability, FSMA 204 demands a comprehensive, end-to-end digital trail. The goal is to allow the FDA to trace a contaminated product back to its source within 24 hours of a request.

The rule applies to any entity that manufactures, processes, packs, or holds foods on the Food Traceability List. If you are processing almonds into almond butter or dicing fresh tomatoes for a salad mix, you are squarely in the crosshairs of this regulation. The FDA’s FTL is extensive, covering commodities where historical data suggests a higher risk of foodborne illness outbreaks. For our industry, this means meticulous tracking of specific events and data points that many facilities currently capture only inconsistently.

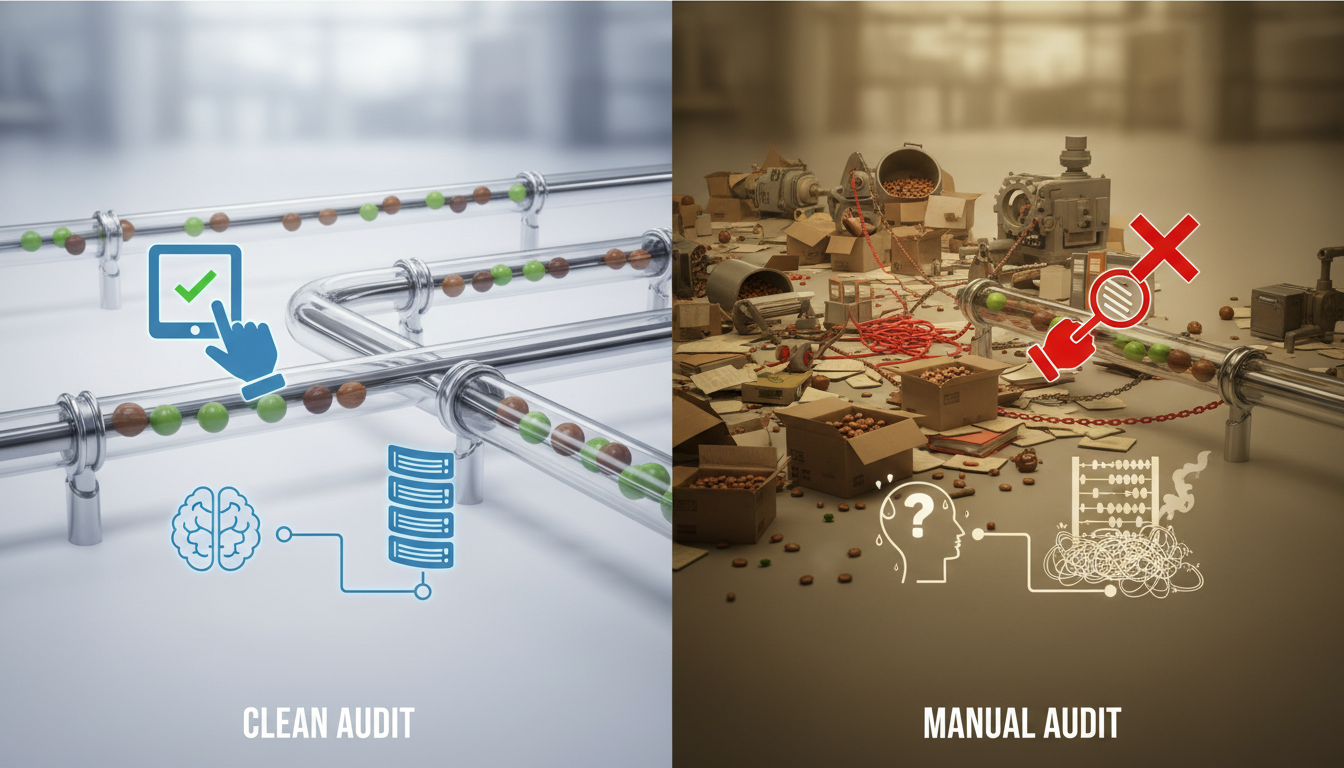

The shift from manual to digital is not merely a recommendation; it is a practical necessity. The volume of data required under the new mandate—specifically the Key Data Elements (KDEs) for every Critical Tracking Event (CTE)—is simply too vast to manage on paper without risking human error and audit failures. As we look toward 2026, the industry is moving toward a standard of digital interoperability, where data flows as seamlessly as the product itself.

Identifying Your Role in the Traceability Chain

Before you can implement a FSMA 204 checklist, you must identify where your facility sits within the supply chain. FSMA 204 defines several Critical Tracking Events (CTEs), and your responsibilities change based on which event you are performing. For most nut and produce processors, you will likely engage in three primary CTEs: Receiving, Transformation, and Shipping.

- Receiving: This occurs when a food is received by an entity in the supply chain. For a processor, this is when the raw agricultural commodities (RACs) arrive from the grower or packer. You must record the Traceability Lot Code (TLC), the location of the source, and the date of receipt.

- Transformation: This is a critical stage for processors. Transformation involves changing a food on the FTL (e.g., chopping, cooking, mixing) or incorporating an FTL ingredient into a new product. When you transform a product, you must create a new Traceability Lot Code and link it to the original lot codes of the ingredients.

- Shipping: This is the physical movement of food from one location to another. You are required to send the KDEs to the next person in the supply chain, ensuring the digital “baton” is passed correctly.

Understanding these roles is vital because FSMA 204 requires a Traceability Plan. This plan must include a description of the procedures you use to maintain records, a description of how you assign Traceability Lot Codes, and a map of your supply chain. In the context of FSMA 204 Compliance and Digital Traceability in Modern Logistics, your role is not just as a processor, but as a data steward.

Automating KDE Collection

The “Key Data Elements” (KDEs) are the specific pieces of information that must be recorded for each CTE. For a busy processing plant, the manual collection of these elements is a recipe for operational bottlenecks. This is where the CVCS Goose System becomes an indispensable tool for the modern Operations Manager.

Automation allows for real-time data capture at the point of action. When a shipment of walnuts arrives, instead of a receiving clerk writing down a lot code on a clipboard, the Goose System scans the GS1-128 barcode, instantly capturing the TLC, harvest location, and timestamp. This digital first-mile data is the foundation of your entire compliance strategy.

The following table illustrates how automation through CVCS replaces manual effort with verifiable, digital precision:

| Required KDE | Source | CVCS Automation |

|---|---|---|

| Traceability Lot Code | Grower/Packer | Scanned at Receipt |

| Date of Cooling | First Mile Facility | Timestamped in Goose |

| Location Description | Facility | Geo-tagged |

By automating KDE collection, you eliminate the “lag time” between the physical event and the record entry. This is crucial during an FDA inquiry. If the FDA requests your traceability records, you must provide them in an electronic sortable spreadsheet within 24 hours. If you are relying on manual logs, you will spend those 24 hours in a state of panic, manually transcribing data. With a digital system, it is as simple as clicking ‘export’.

The FSMA 204 Checklist for Processors

To prepare for the 2026 deadline, Operations Managers should follow this systematic checklist to ensure their facility is ready for the transition.

Step 1: Conduct a Gap Analysis

Review your current recordkeeping practices. Do you currently record the Traceability Lot Code for every incoming FTL item? Do you have a mechanism to link the incoming lot code to the new lot code generated during transformation? Most processors find that while they have “internal lot numbers,” they lack the “Traceability Lot Code” continuity required by the FDA.

Step 2: Map Your Critical Tracking Events

Identify every point in your facility where an FTL product is received, transformed, or shipped. For each point, list the KDEs required. For instance, during transformation, you must record the new TLC, the date transformation was completed, and the quantity and unit of measure. Mapping this visually helps in identifying where digital sensors or scanning stations should be placed.

Step 3: Establish a Traceability Lot Code (TLC) Protocol

The TLC is the “golden thread” of FSMA 204. It must stay with the food as it moves through the supply chain. As a processor, you cannot change the TLC of an incoming product unless you transform it. Your system must be capable of storing the original TLC and generating a new one that maintains a digital link to the source. The Goose System automates this linkage, ensuring that the “ancestry” of every nut butter jar or bagged salad is preserved.

Step 4: Implement Digital Interoperability

FSMA 204 encourages the use of international standards like GS1 for data exchange. Your traceability system must be able to “talk” to your suppliers’ and customers’ systems. Moving toward a digital-first approach means using electronic data interchange (EDI) or cloud-based platforms that allow for the seamless transfer of KDEs. Manual logs will no longer be sufficient; digital interoperability is now a regulatory necessity.

Step 5: Train Your Operations Team

Compliance is only as good as the data entered by your floor staff. Training is essential to ensure that every scan is performed correctly and every transformation event is logged in real-time. An intuitive system like Goose reduces the learning curve, making compliance a natural part of the workflow rather than an additional burden.

The Role of Nut Butters and Produce in the FTL

The FDA’s Food Traceability List includes nut butters, fresh produce, and various agricultural commodities for a reason. These products have been linked to significant multi-state outbreaks. For nut processors, the transformation of raw nuts into nut butters is a high-risk CTE. The roasting, grinding, and blending processes must be documented with absolute precision. If a batch of peanut butter is flagged for Salmonella, the processor must be able to identify exactly which raw lots were used and where those finished jars were shipped.

Similarly, in the produce sector, the “Date of Cooling” and “Location Description” are vital KDEs. Produce is highly perishable, and the speed of a recall can be the difference between a minor incident and a public health crisis. By using geo-tagged location descriptions and automated timestamps, processors can provide the FDA with the level of granular detail required to narrow the scope of a recall, potentially saving the company millions of dollars in lost inventory.

Why the 2026 Deadline Matters Now

While January 20, 2026, might seem far away, the complexity of implementing a full-scale digital traceability system cannot be understated. It requires hardware installation, software integration, and a fundamental shift in company culture. Waiting until 2025 to begin your transition is a high-risk strategy that could lead to non-compliance and market exclusion.

Major retailers are already beginning to demand FSMA 204-compliant data from their suppliers. Being an early adopter of digital traceability provides a competitive advantage. It signals to your customers that you prioritize food safety and that your supply chain is transparent and resilient.

Frequently Asked Questions (FAQ)

- Q: What is the deadline for FSMA 204?

A: The compliance date for all affected entities is January 20, 2026. - Q: Can I use paper records for FSMA 204?

A: While the law technically allows for paper records, you must be able to provide the FDA with an electronic sortable spreadsheet of your traceability data within 24 hours of a request. For most operations, this makes digital recordkeeping the only viable option. - Q: Does FSMA 204 apply to small farms?

A: There are certain exemptions for small producers based on annual sales, but most commercial processors will find themselves required to comply, especially if they sell to mid-to-large size retailers.

Conclusion: Moving Toward a Digital Future

The implementation of FSMA 204 is a landmark moment for the food industry. For those of us in operations, it represents a shift from reactive fire-fighting to proactive, data-driven management. By focusing on the FSMA 204 checklist and leveraging automation tools like the CVCS Goose System, processors can turn a regulatory burden into an operational strength.

The goal is simple: a safer food supply through better data. By capturing KDEs at every CTE and ensuring digital interoperability, we are not just checking a box for the FDA—we are building a more transparent, efficient, and trustworthy food system for everyone.